High Performance Clean Diesel – HPCD™

~ A highly refined diesel fuel produced by EcoChem’s patent pending, diesel re-refinement process that brings the most advanced fuel enhancement technologies together at the point of dispensing.

Benefits of HPCD™

![]() Reduces emissions up to 25%

Reduces emissions up to 25%

![]() Averaging 11% improvement in MPG

Averaging 11% improvement in MPG

![]() Exceeds fuel cleanliness standards for ISO & OEM’s

Exceeds fuel cleanliness standards for ISO & OEM’s

![]() Up to 35% more lubricity than ULSD

Up to 35% more lubricity than ULSD

![]() Better cold starts in low winter temperatures

Better cold starts in low winter temperatures

HPCD™ has a higher combustion efficiency, producing more horsepower and (or) better MPG while creating less Volatile Organic Compounds (VOC) than commercial diesel fuel.

HPCD is the ultimate protection for critical engine components from poor quality, consumer grade diesel fuel. No other known commercial technology presents both purification and molecular enhancements that EAF’s HPC-Fuel processing system provides.

This makes HPCD the best choice fuel that meets and exceeds ISO & OEM standards as required by engine manufacturers to warranty their equipment. This will eliminate the host of current fuel challenges and provide a high performance, cleaner burning fuel.

Solving consumer-grade fuel problems with HPCD technology

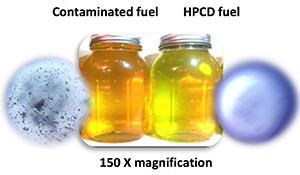

Microbial contamination and fuel-borne particulate clogs fuel lines and reduces combustion efficiency. – HPCD fuel refinement process removes all but trace amounts of microbial causing agents and particulate.

Corrosion throughout the fuel system occurs when water is introduced into the fuel from either outside the system or through condensation. – HPCD fuel refinement process removes water and other hydroscopic elements without emulsification, which increases injector life.

Gumming of fuel takes place due to the presence of olefinic hydrocarbon fractions that are left over in the refining process. These “fractions” easily oxidize leaving a gum-like residue clogging the fuel system and preventing efficiency. – HPCD fuel uses proprietary molecular correction technology that motivates hydrocarbon fracturing, prevents gumming and makes HPCD the most stable diesel fuel available.

Carbon build-up creates an extremely hard, difficult to remove material that inhibits combustion, reduces performance and causes extra wear. – HPCD fuel removes carbon deposits from the fuel system, thus the engine achieves greater performance, less emissions, and decreased maintenance costs.

Incomplete combustion leads to harmful emissions and internal carbon build-up. This problem universally occurs in gasoline and diesel engines. – HPCD fuel optimizes combustion by creating a catalyzed combustion reaction that transforms hydrocarbon chains into equal length.

Uneven heating of the combustion chamber causes excessive wear and premature failure from material fatigue. Inefficient combustion is neither fast nor symmetric and as a result heat is not evenly disbursed throughout the combustion chamber. – HPCD fuel yields enhanced properties that protect combustion surfaces, valves, and valve seats and creates a catalytic environment that produces a complete, quick and efficient burn rate.

Exhaust gas temperatures Increased exhaust gas temperatures are highly detrimental to any engine, will increase maintenance intervals and harm expensive exhaust components. – HPCD fuel lowers exhaust gas temperatures equaling longer maintenance intervals and lower operating costs.

Cold starts account for up to 90% of engine wear causing extremely adverse effects to vital engine components. – HPCD fuel purity, stability and higher cetane will lower the cold start impact on the upper cylinder, valves and valve seats and piston rings.

Lubrication is not a feature of today’s ultra-low sulfur diesel. By removing the natural lubricating properties of sulfur, ULSD lacks the ability to lubricate expensive engine components, pumps and injectors. – HPCD fuel tested 35% higher lubricity when compared to ULSD. This can prolong engine life, and protect the life of injector pumps and injectors.